Electromechanical Universal Test Machine

Product Code

UTM-8100.SMD2 | Electromechanical Universal Test Machine, 100 kN |

UTM-8300.SMD2 | Electromechanical Universal Test Machine, 300 kN |

Models for 220-240 V 50-60 Hz, 1ph. | UTCM-8100.SMD2 | UTCM-8300.SMD2 |

Models for 110-120 V 60Hz, 1ph. | UTCM-8100.SMD2-N | UTCM-8300.SMD2-N |

Standards

ISO 7500-1

UTM-8100, 100 kN and UTM-8300, 300 kN capacity fully automatic UTEST Electromechanical Universal Testing Machines are multi purpose versatile machines which satisfy the requirement of R&D laboratories, university laboratories, institute laboratories and quality control laboratories for tensile, compression flexural tests under load or displacement control for a wide range of materials UTM 8100 and UTM- 8300 model Electromechanical Universal Testing Machines can be used for tensile test on any material i.e (metal, plastic, textile, wood) by using suitable accessories. Those machines can also be used for general compression, flexural, tests on steel, soil, concrete, cement, rock, asphalt and similar materials, by using suitable accessories.

These Testing Machines consist of base containing the transmission components and holds two robust columns connected by upper cross head and digital graphics data acquisition and control system. The upper cross head can be adjusted to set the vertical test space for different tests. User can adjust the vertical test space by also lower crosshead moved by an electromechanical system with a single recirculating ball screw, powered by an servomotor.

Advanced closed loop control system assures accurate load or displacement pace rate on sample.

The load is measured by a load cell that located on upper crosshead and displacement is measured by an encoder fit to the servo motor on both models.

The operator will have large flexibility during the test with advanced microprocessor control and material testing software installed on PC.

UTM-8100 supplied with compression platens and load cells 50 kN capacity.UTM-8300 supplied with compression platens and load cells 300 kN capacity

Gripping systems, extensometers and accessories are not included and have to be ordered separately.

Frame Features

| UTM-8100.SMD2 | UTM-8300.SMD2 |

|---|---|---|

Max. Load | 100 kN | 300 kN |

Max. Vertical Test Space (without accessories) (Lower crosshead at middle stroke. |

650 mm |

850 mm |

Distance Between Columns | 440 mm | 630 mm |

Crosshead Travel | 400 mm | 200 mm |

Test Speed Range | 0-100 mm/min. | 0-75 mm/min. |

Load Rate | 0,001-2 kN/s (Depend on specimen stiffness) | 0,001-10 kN/s (Depend on specimen stiffness) |

Machine Class

| Class 1 starting from 1% of the capacity | Class 1 starting from 1%of the capacity |

Encoder Resolution | 0.001mm | 0,001 mm |

Encoder Accuracy | 0,01 | 0,01 |

Overall Dimensions | 1300x520x2300 mm | 1100x450x1860 mm |

Weight Approx. | 400 kg | 800 kg |

ACCESSORIES

General Accessories;

- -UTGM-0010 Load Cell, 5 kN Capacity, S Type

- -UTGM-0015 Load Cell, 10 kN Capacity, Pancake Type

- -UTGM-0020 Load Cell, 20 kN Capacity, Pancake Type

- -UTGM-0025 Load Cell, 50 kN Capacity, Pancake Type

- -UTGM-0030 Load Cell, 100 kN Capacity, Pancake Type

- -UTGM-0035 Load Cell, 300 kN Capacity, Pancake Type

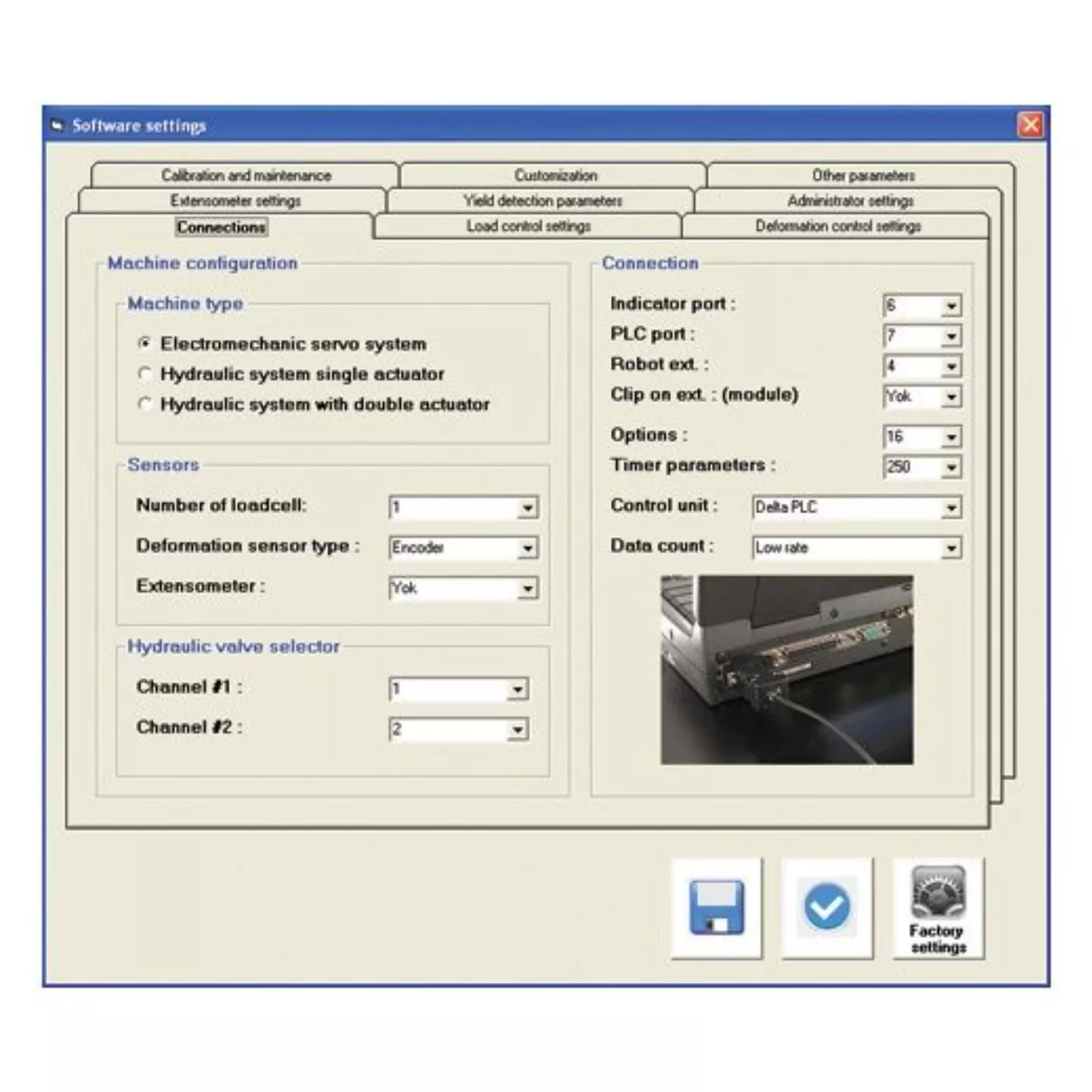

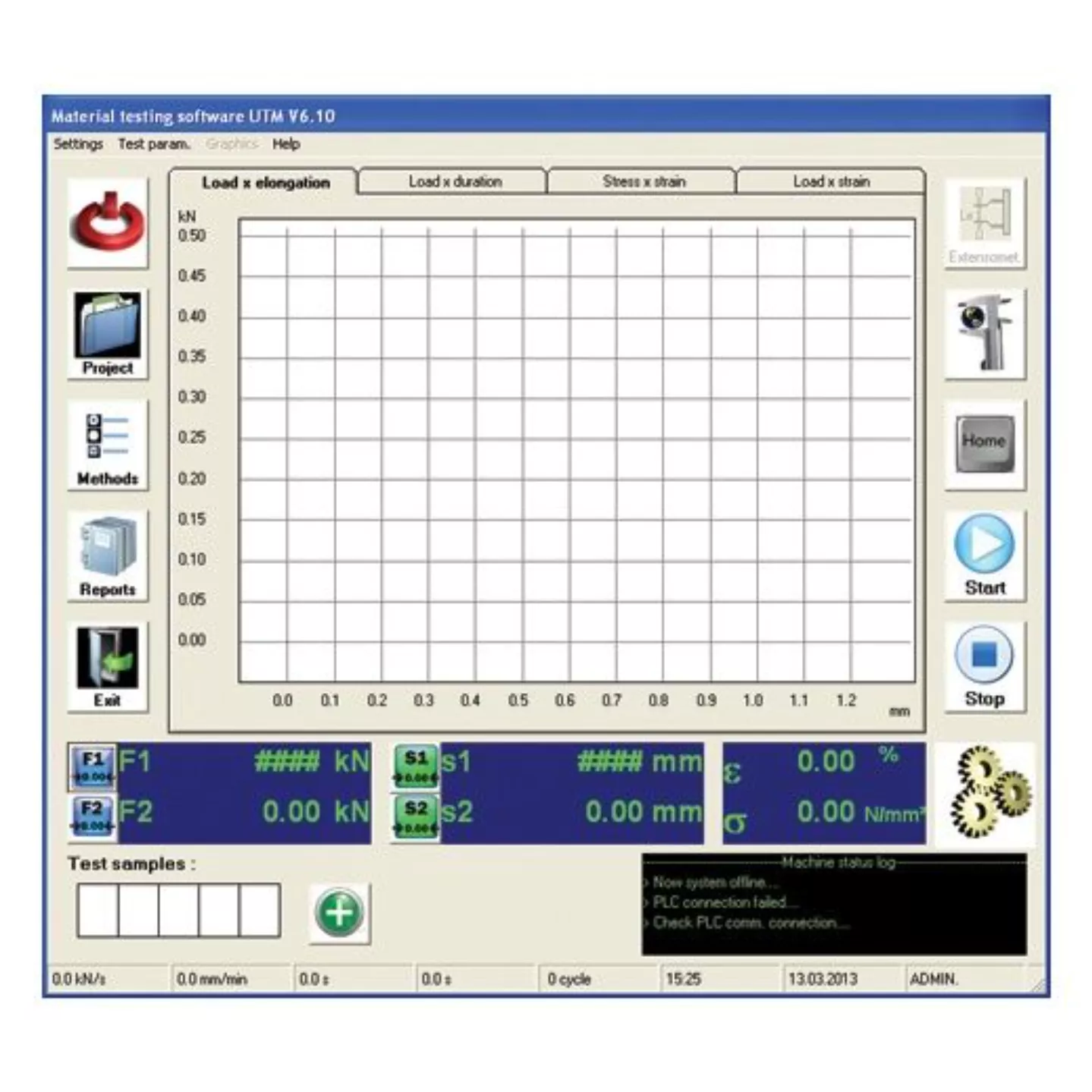

Data Acquisition & PC Software

Digital display graphics data acquisition and control system are designed to control the machine and process the data from encoders, Load cells, installed on the Electromechanical Test Machine frame. It has graphical TFT display of 240x128 pixel and show both load and displacement. The digital unit sends all these information to PC and accepts commands of Start, Stop, and Test Speed etc.

Manual zeroing of all engineering values exist prior to the beginning of test.

Materials testing software is available for Utest UTM series universal testing systems. Test software provides fully customized parameter definition, test method development tools, automatic test control, data collection, results analysis, and reporting.

This flexible software solution supports multiple testing technologies and test types, allowing you to standardize your lab under a single software application. With several options for creating tests, and a separate application for running tests, you can allocate resources in the way that makes sense for your lab.

Advanced templates for testing to ASTM, ISO and EN standards for tension testing, compression testing, flexure testing, and more across a wide variety of materials and applications help ensure quick and efficient test setup and execution.

Various engineering calculations are performed automatically such as strain, tensile stress, compressional and flexural strength, elongation, yield point, elasticity modulus, absorbed energy, etc. with the software

Test results stored in computer for your future retrieve or reanalysis and reporting. Data Exchange between other Windows based applications such as Excel, Word or output in PDF format.

MATERIAL | TEST/METHODS | STANDARDS | ACCESORIES |

|---|---|---|---|

STEEL (ROUNDS AND FLATS) | Tensile Test under Load/Displacement Control | EN ISO 6892-1 | UTM-8410 Tensile Grip, 100 kN, complete with jaw faces for round specimens from Ø4 to Ø9 mm and Ø9 to Ø14 mm, for flats 0 to 7 mm and 7 to 14 mm thick

UTM-8430 Tensile Grip, 300 kN, complete with jaw faces for round specimens from Ø8 to Ø16 mm and Ø16 to Ø24 mm, for flats 0 to 9 mm and 9 to 18 mm thick

UTM-8055 Holder for Weld Shear Force Tests for welded fabric |

CEMENT AND MORTARS | Compression Test Under Load Control | EN 196-1 ASTM C109 | UTCM-4210E Compression Jig Assembly EN, to test portions of 40,1x40x160 mm cement mortar prisms. (*)

UTCM-4210A Compression Jig Assembly ASTM, to test 50 mm (2") cubes. (*) |

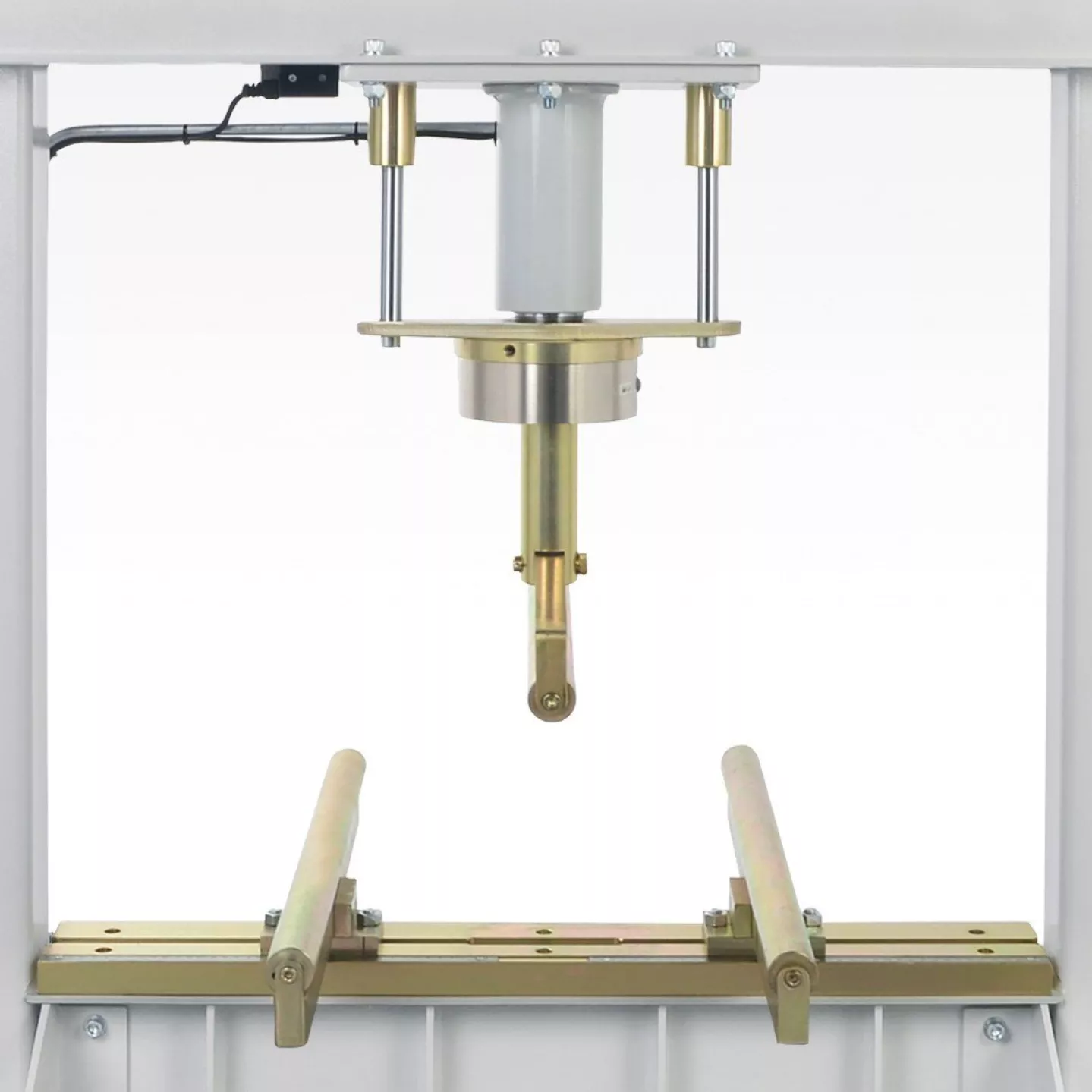

Flexure Tests Under Load Control | EN 196-1 ASTM C348 EN 12808-3 EN 1015-11 | UTCM-4200E Flexure Jig Assembly EN, to test 40,1x40x160 mm cement mortar prisms

UTCM-4200A Flexure Jig Assembly ASTM, to test 40x40x160 mm mortar prisms, | |

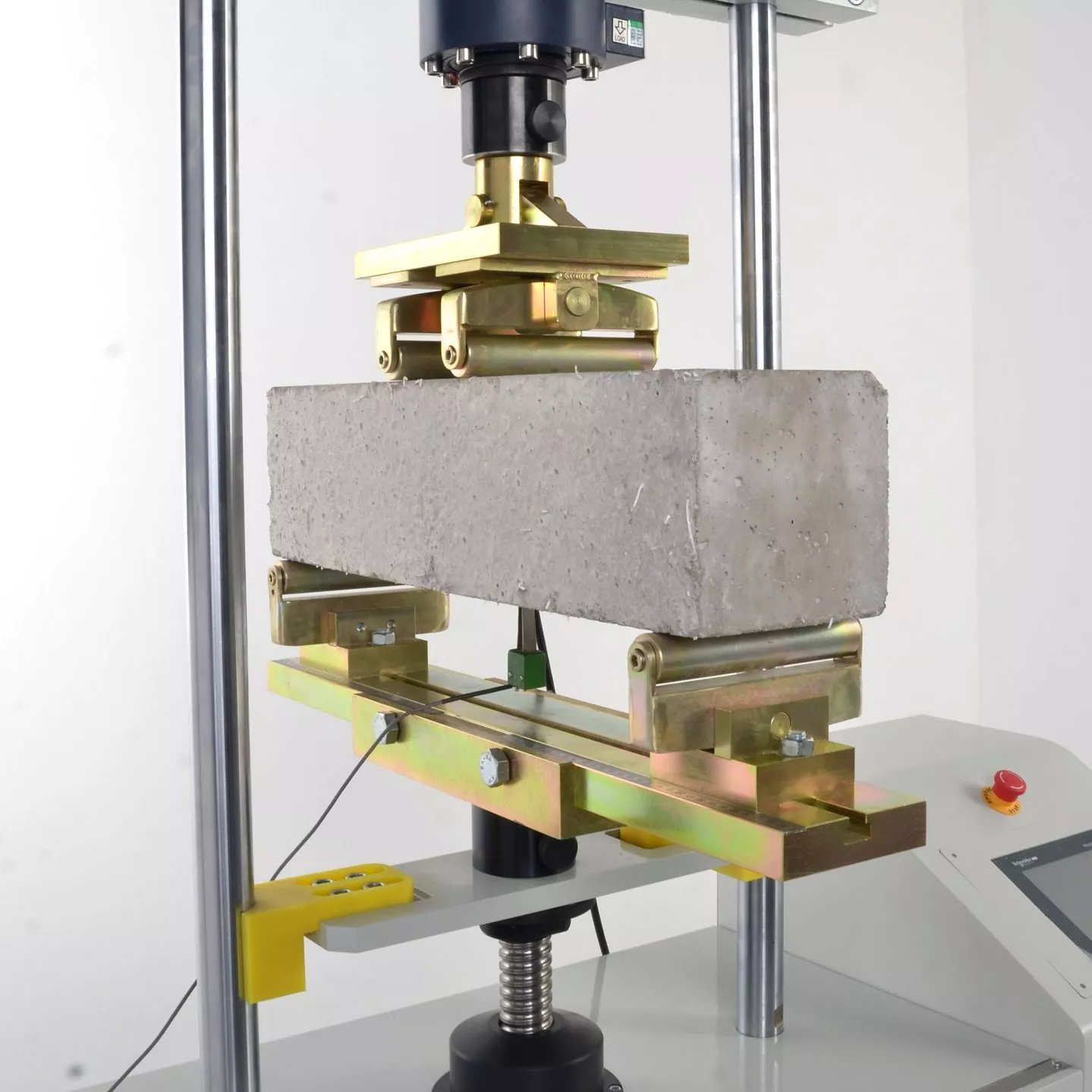

CONCRETE | Flexure Tests on Concrete Beams under Load Control | EN 12390-5 ASTM C78, C293 AASHTO T97 BS 1881:118 | UTC-5501 Bearers, used for 3 or 4 point flexural tests on concrete beams of 100x100x400-500 mm, 150x150x600-750 mm. |

Flexure Tests on Concrete Kerbs Under Load Control | EN 1340 | UTC-5502 Flexural Testing Assembly for Concrete KerbsBearers. Consist of two lower roller of 38 mm dia. x 620 mm length and upper load point of 40 mm Dia with ball seating, 300kN | |

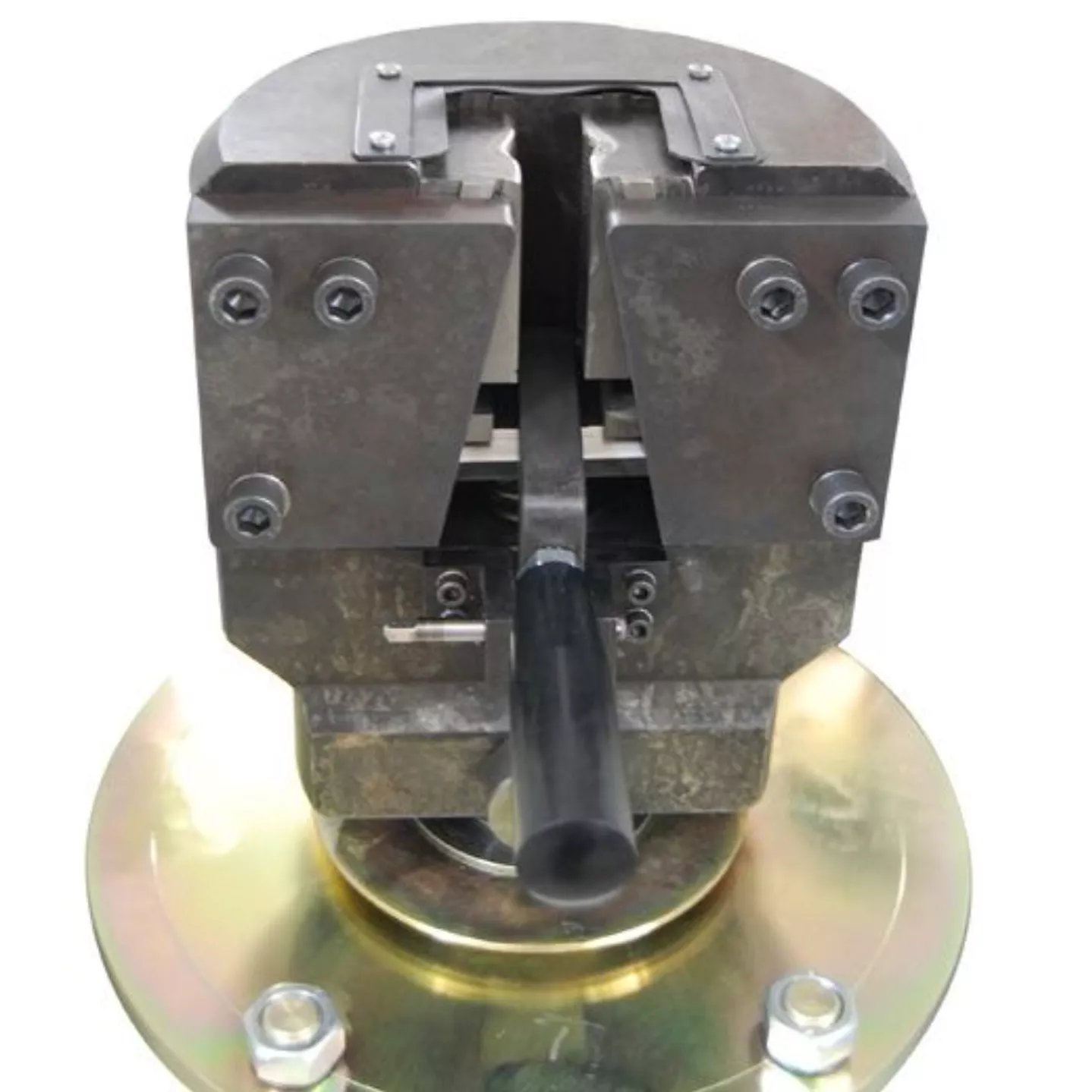

Splitting Tests on Concrete Cylindrical and Cubes Specimens, and concrete paving blosks under Load Control | EN 12390-6 AASHTO C496 EN 1338 | UTC-0350 Splitting tensile test device for 100x200 mm (4" x 8"), 150x300 mm (6" x 12")

UTC-0351 Distance piece for UTC-0350E, for Ø100x200(Ø4x8") mm and Ø110x220mm

UTC-0360 Splitting tensile test device for 150 mm concrete cubes (EN)

UTC-0361 Distance piece for UTC-0360, for 100 mm cubes specimens, EN.

UTC-0355 Splitting tensile test device for 60-100x220 mm (hxl) concrete block pavers. (EN) |

- -(*) Up to the machine capacity

- -(**) Supplied complete with the connectiion appratus fit with the ordered machine.

SOIL | CBR Under Displacement Control | EN 13286-47 ASTM D1883 AASTHO T193 | UTS-0870 CBR Penetration piston

UTGM-0064 LPDT (linear potentiometric displacement transducer ) 50 mm x 0.001 mm

UTM-0114 Holder for UTGM-0062 and UTGM- 0064

UTGM-0025 Load Cell, 50 kN Capacity, Pancake Type |

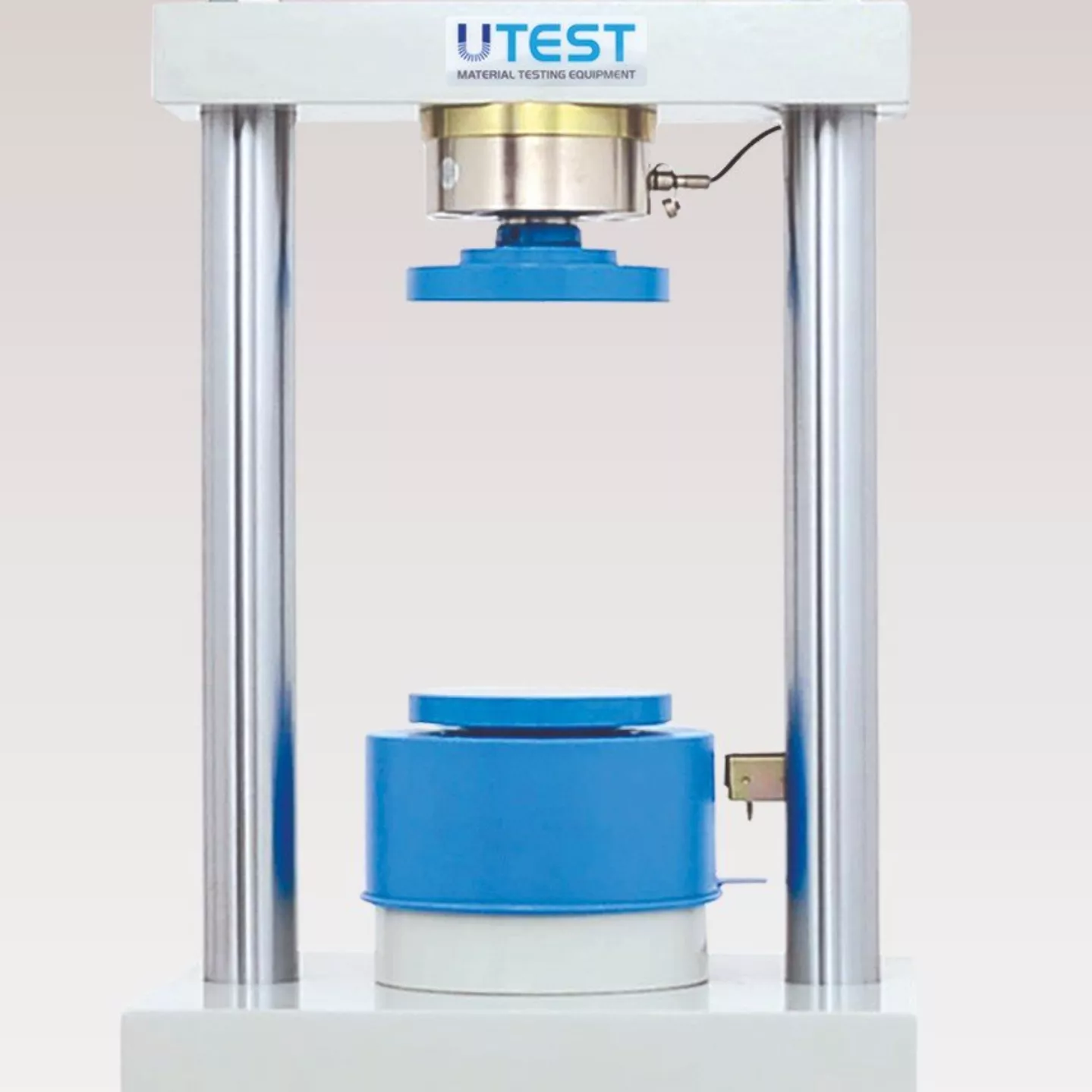

BITUMINOUS MIXURES | Marshal Test Under Displacement Control | EN 12697-34 ASTM D1559 | UTM-1086 Marshall Penetration Piston for UTM-0108, UTM-8100 and UTM 8300

UTGM-0064 LPDT (linear potentiometric displacement transducer ) 50 mm x 0.001 mm

UTM-0114 Holder for UTGM-0062 and UTGM- 0064

UTAS-1057 Breaking Head (Stability Mould), cast iron, for 4" (101,6 mm) Marshall Samples

UTAS-1058 Breaking Head (Stability Mould), cast iron, for 6" (152,4 mm) Marshall Samples

UTGM-0025 Load Cell, 50 kN Capacity, Pancake Type |

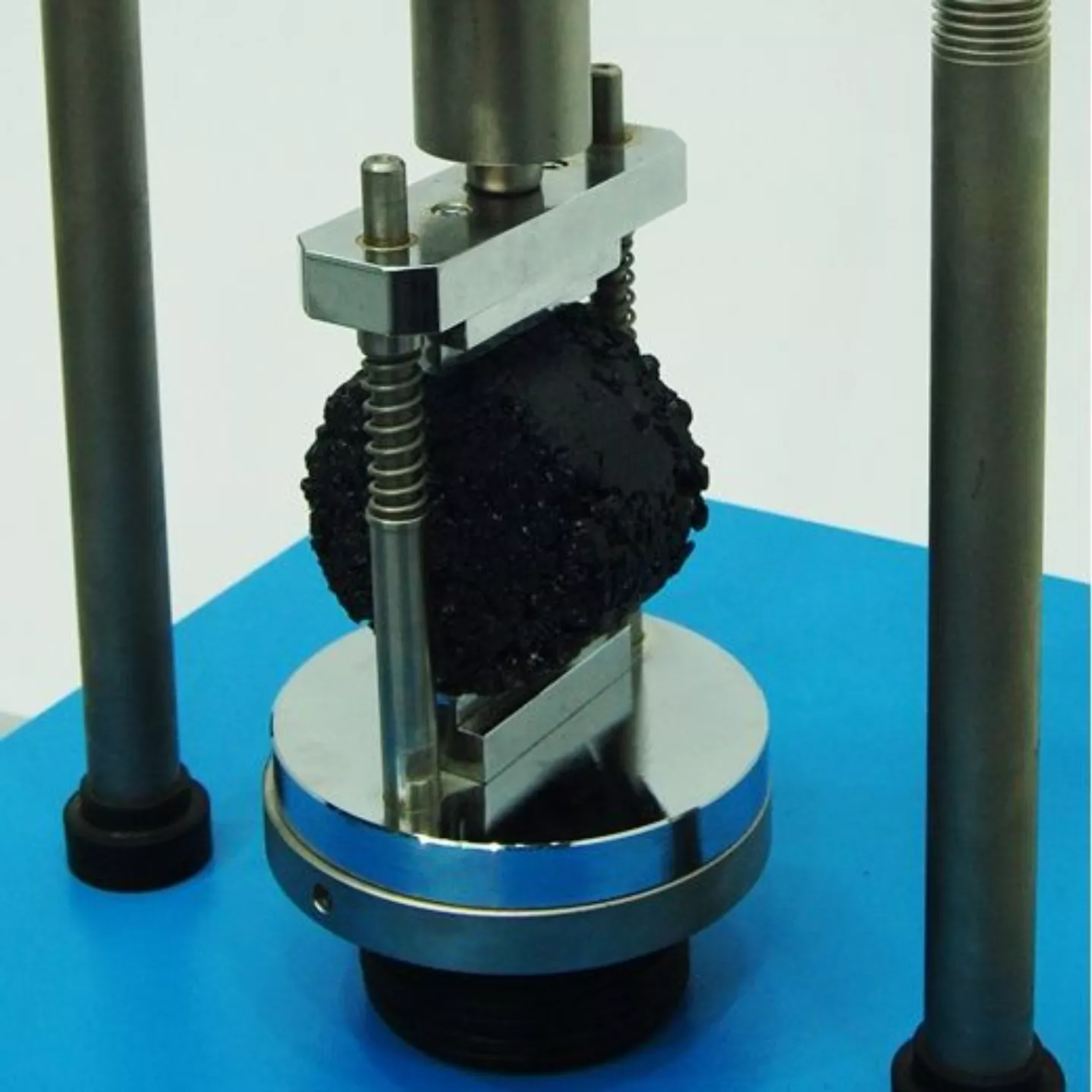

Indirect Tensile Splitting Tests | EN12697-23 AASHTO T283 | UTAS-1063E Indirect Tensile Strength Test jig (EN), supplied with steel loading strips for Ø100 mm bituminous specimens .

UTAS-1064E Pair of oading strips for Ø150 mm bituminous specimens.

UTAS-1065E Pair of loading strips for Ø160 mm bituminous specimens

UTAS-1063A Indirect Tensile Strength Test jig (ASTM), supplied with steel loading strips for Ø4"(101,6mm) bituminous specimens

UTAS-1066A Pair of loading strips for Ø6"(152,4mm) bituminous specimens

UTM-1086 Marshall Penetration Piston for UTM-0108, UTM-8100 and UTM 8300

UTGM-0064 LPDT (linear potentiometric displacement transducer ) 50 mm x 0.001 mm

UTM-0114 Holder for UTGM-0062 and UTGM- 0064 | |

Duriez Test Under Displacement Control | NF P98 251 1/4 EN 12697-12 Method A and B | UTAS-0490 Duriez Compression Test Set, 80 mm diameter. Only with UTM-8300

UTAS-0500 Duriez Compression Test Set, 120 mm diameter. Only with UTM-8300 |

Français

Français English

English