- Binder Content

- Laboratory Mixers

-

Marshall Compaction

- Marshall Compaction Mould

- Marshall Manual Compaction Assembly, ASTM

- Automatic Marshall Impact Compactor, EN

- Automatic Marshall Impact Compactor for 4” Speciments, ASTM

- Automatic Marshall Impact Compactor with Stationary Base for 4” and 6” Speciments, ASTM

- Marshall / CBR / Proctor Specimen Extruder

- Duriez Compression Test Sets

- Vibratory Hammer for Compaction of Bituminous Mixtures and Soil

- Marshall Stability

- Core Drilling

- Asphalt and Road Quality Testing

- Home ›

- Products ›

- ASPHALT ›

- Automatic Marshall Impact Compactor, EN

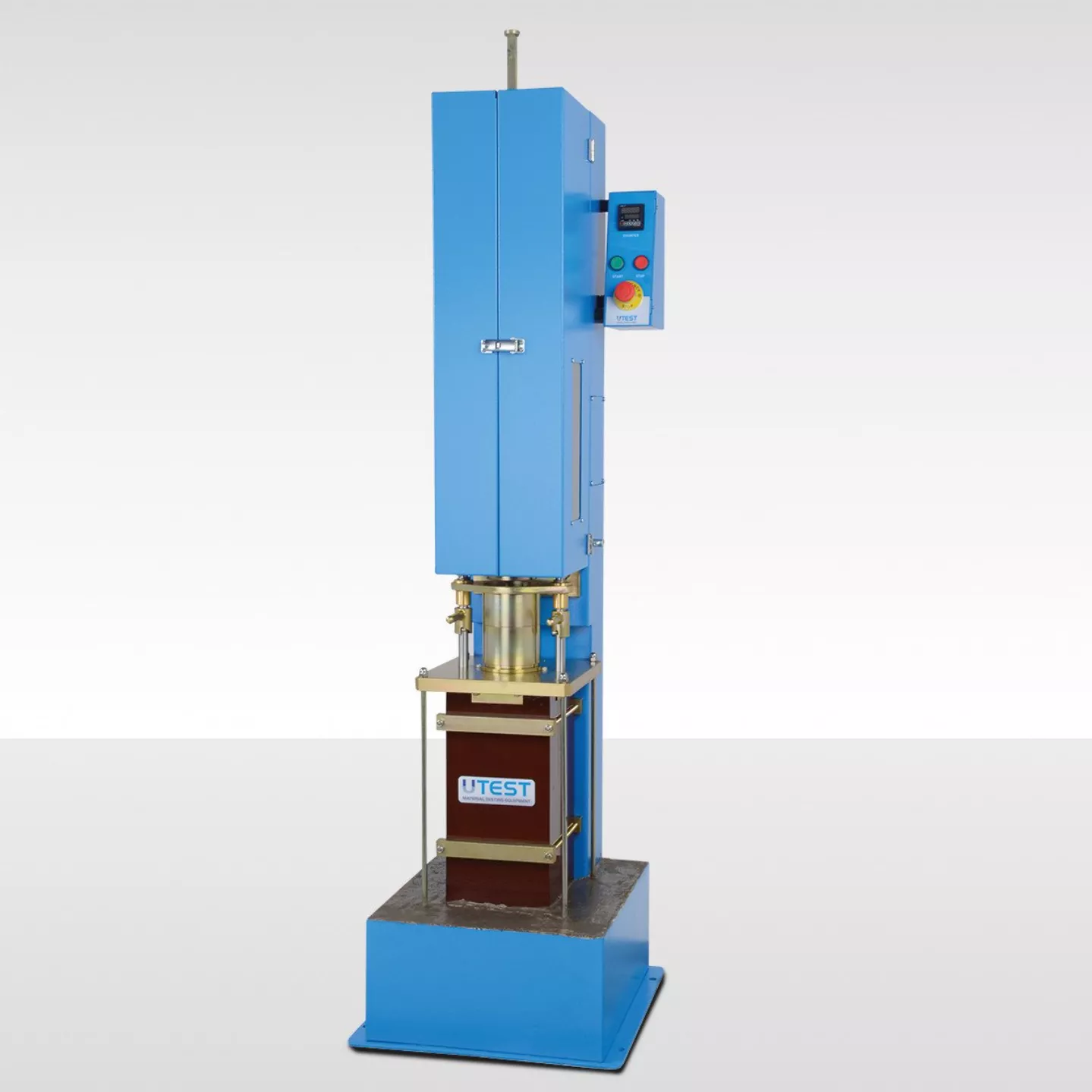

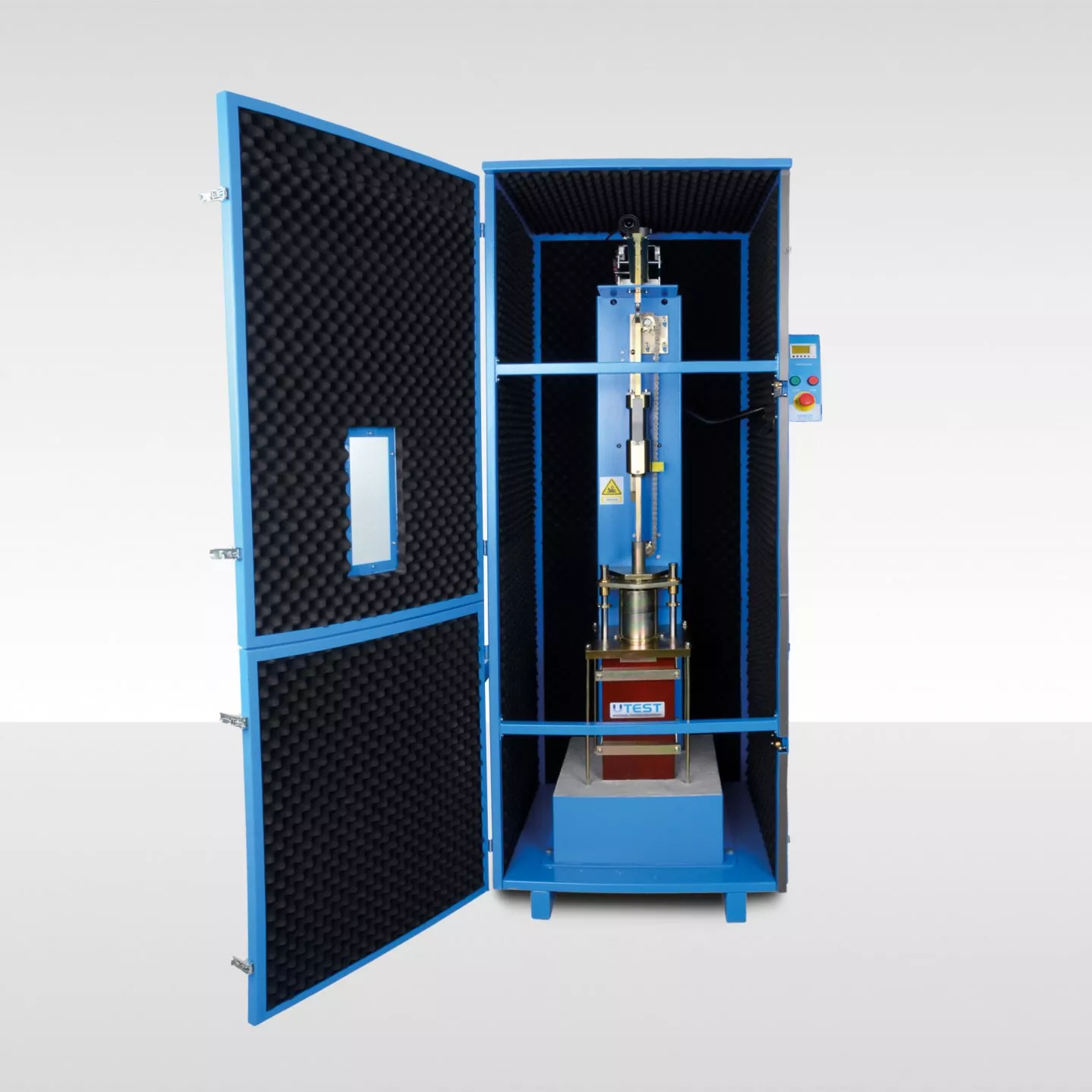

Automatic Marshall Impact Compactor, EN

Product Code

UTAS-0682E | Automatic Marshall Impact Compactor with Wooden Pedestal, EN |

UTAS-0683E | Automatic Marshall Impact Compactor with Wooden Pedestal and Soundproof Safety Cabinet |

UTAS-0667 | Marshall Steel Block, Ø102 and 50 mm height |

UTAS-0641E | Marshall Compaction Mould for Impact Compactor with Wooden Pedestal, EN, 101.6 mm |

Models for 220-240V 50 Hz, 1 ph. | UTC-0682E-T | UTC-0683E-T |

Models for 110-120V 60 Hz, 1 ph. | UTC-0682E-N | UTC-0683E-N |

Models for 220-240V 60 Hz, 1 ph. | UTC-0682E-K | UTC-0683E-K |

Standards

EN 12697-30, 12697-10, 12697-12

The UTAS-0682E and 0683E Automatic Marshall Compactor with wooden pedestal provides a uniform and even degree of compaction. The unit incorporates a compaction pedestal, comprising a laminated hardwood block secured to a concrete block by a 300 mm square x 25 mm thick steel plate.

The conveniently positioned control panel comprises of start/stop button, emergency stop button and a direct reading counter used to set the required number of blows. The apparatus stops automatically after the preset number of blows.

The compactors are equipped with a hand operated Mould fixing mechanism which locks the Mould in place during compaction and reduces vibration of the Mould.

The standard model can be supplied with a safety/noise reduction cabinet. The cabinet is lined internally with soundproofing material to reduce sound level conforming to CE directives.

Particular attention has been paid to operator safety by the inclusion of various in-built safety features.

UTAS-0667 Marshall Steel Block which can be used for Initial heating of the foot of compaction hammer and Marshall Moulds should be ordered separately.

Technical Specifications

Blows Frequency | 50 blows in 55 s to 60 s |

|---|---|

Free fall height of the sliding mass | 457±3 mm |

Total weight (Guide rod + Foot assembly+ Sliding mass) | 7850 ± 50 g |

Concrete Base Dimension | 450x450x200 mm |

Laminated Hardwork Block Dimensions | 200x200x450 mm |

Laminated Hardwork Block Density | 0,67 Mg/m3 to 0,78 Mg/m3 |

Product Code | UTAS-0682E | UTAS-0683E |

|---|---|---|

Dimensions | 520x520x1760 mm | 770x870x1970 mm |

Weight (approx.) 225 kg | 235 kg | 362 kg |

Power | 370 W | 370 W |

Français

Français English

English