- Home ›

- Products ›

- BITUMEN ›

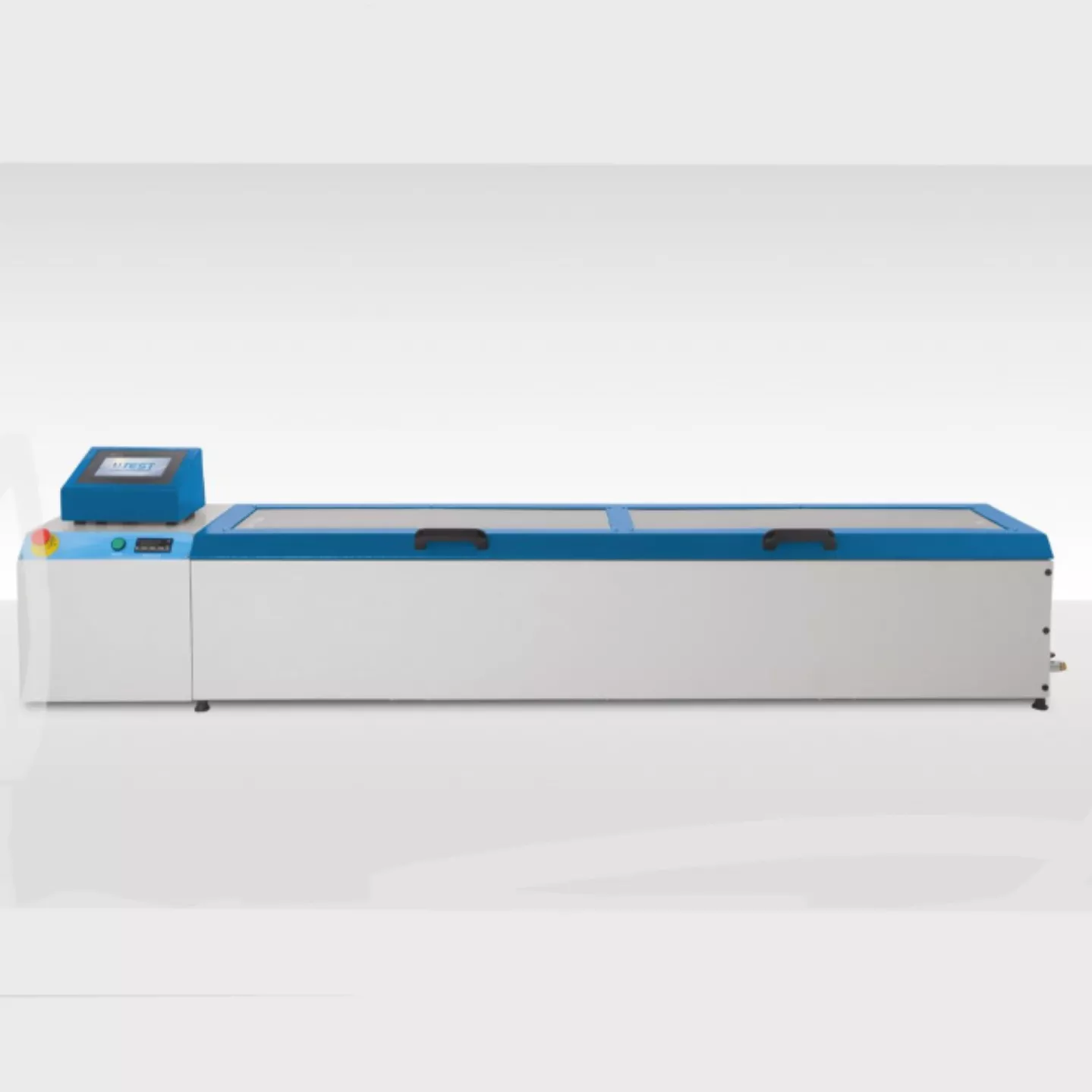

- Force Ductility Testing Machine

Force Ductility Testing Machine

Product Code

UTB-1430 | Force Ductility Testing Machine |

UTB-1402A | Ductility Briquette Mould, Brass, ASTM D113 and AASHTO T51 |

UTB-1402NF | Ductility Briquette Mould, NF |

UTB-1403A | Ductility Briquette Mould, Brass, AASHTO T301 |

UTB-1405 | Ductility Mould Base Plate, For One Mould, Brass |

UTB-1405-3 | Ductility Mould Base Plate, For Three Moulds, Brass |

UTB-1406A | Ductility Mould, Brass, ASTM D6084, AASHTO T300 |

UTB-1406E | Ductility Mould, Brass, EN 13589 |

UTB-1408E | Ductility Mould, Brass, EN 13398 |

UTGE-4110 | Open System Cooler / Circulator Unit |

Models for 220-240V 50-60 Hz, 1 ph. | UTB-1430 | UTGE-4110 |

Models for 110-120V 60 Hz, 1 ph. | UTB-1430-N | UTGE-4110 -N |

Standards

EN 13589, 13398, 13703; ASTM D113, D6084; AASHTO T51, AASHTO T300

The UTB-1430 Force Ductility Testing Machine is used to determine the the deformation energy required to stretch a bitumen sample from 200 mm elongation to 400 mm elongation. Force ductility machine is capable of testing 3 specimens simultaneously. The speed of the machine can be adjusted from 5 mm/ min. to 100 mm/ min. Internal tank is made of stainless steel. The bath is fitted with an immersion heater in order to obtain the 25°C test temperature required for normal ductility testing.

Water bath is covered by insulating material to reduce the heat loss during testing.

The machine can be supplied with an external Cooler / Circulator Unit necessary to obtain the 5°C test temperature required for force ductility testing according to EN 13589.

UTB-1430 Force Ductility Testing Machine has 3 load cells. The accuracy of load cells are ±0,1N with a maximum capacity of 300 N. Test speed can be adjusted and load-displacement curves can be drawn through the software. Software for UTB-1430 is capable of calculating deformation energy according to EN 13589 and displaying force vs displacement graphs for each sample separately or on the same screen.

Cooler/Circulator Unit (UTGE-4110), Moulds and Mould base plates should be ordered separately.

Main Features

• Elongation measurement through motor encoder.

• 3 simultaneous load measurements with 18 bit resolution.

• Ethernet for connection to PC (not included).

• Color large TFT graphic display with touch screen

• PID controlled heating and cooling system.

• Fine adjustment of test starting position for easy insertion and removal of different types of test Moulds.

• Closed-loop PID temperature control of 25±0.5°C

• Temperature range from 4°C to ambient temperature ( ±0.5°C ) with the Cooler / Circulator Unit

(UTGE-4110)

Software

• Selection of test parameters can be made either by TFT graphic display or computer software.

• Automatic calculation of deformation energy.

• Display of load vs deformation graphs.

• Software assistance for elastic recovery test according to EN 13398 to minimize operator error.

UTB-1430 | |

|---|---|

Dimensions | 460x2250x610 mm |

Weight (approx.) | 130 kg |

Power | 350 W |

UTGE-4110 | |

|---|---|

Dimensions | 600x900x670 mm |

Weight (approx.) | 89 kg |

Power | 350 W |

Français

Français English

English